Indianapolis Residents - Learn Lean Six Sigma’s History Here

Contact Us

Some people believe Lean Six Sigma History is easy to go over and understand. However, this can prove to be a challenge by the simple fact that it involves more than one methodology, more than one time in history, and more than one principle. At Lean Six Sigma Curriculum for Indianapolis High School Students of Indiana, we want to make sure each one of our students understands and learns the history of this method as it helps expand knowledge and comprehend how it works and why. Moreover, how it is useful for individuals and not only companies nowadays.

First, you should know that LSS focuses on reducing waste, improving processes, achieving continuous improvement, and working towards reducing costs and increasing revenue. This is all based on how companies need to work around their processes and how they need to identify problems or issues and control them after implementing solutions so they don’t repeat.

But where did all this idea of LSS come from? This is what takes us to history.

LSS was established to address the problem of Japanese companies dominating production and markets in the 1980s as American industries were falling behind in both customer satisfaction and quality.

Japan followed and implemented a large variety of methodologies, but the main one is the Kaizen method, which focuses on customer satisfaction and waste reduction in specific.

To compete with this, U.S. companies decided to implement LSS, which is a method that actually comes from Lean and 6 Sigma, two individual methodologies.

How Do Japanese Methodologies Influenced LSS?

Before you can implement Lean Six Sigma or dive deeper into the past, it is important to be aware of how even methodologies from competitors boosted the idea of Sigma as a whole since it isn’t just a combination of the previous two mentioned—and which we will talk more about later.

Some we can mention include:

- Kanban method for workflow management.

- Value stream mapping for optimizing process delivery.

- A five steps method to optimize work and guarantee efficiency.

They are all part of the competing methods back in the 80s and are also part of LSS’s bases today.

Now, Lean and Six Sigma don’t actually come from Japan. They originated in the USA, although there is some more background about this.

Lean and Six Sigma: Inception and Purpose

Toyota developed Lean in the late 1940s as a way to reduce non-value-adding activity and ensure improvement with the right processes.

Lean management’s core values include:

- Focusing on customer service and satisfaction.

- Reduce all work-related waste.

- Continuous improvement while still focusing on clients.

Toyota Production Systems (TPS), which is where Lean was first established, is also where we first notice its usage. Its founder, Japanese Taiichi Ohno, was the originator of Lean’s foundations.

Some data shows that Lean was founded upon Henry Ford’s innovations, Business Process Redesign, and other business processes.

We can see that Lean is a way to improve our lives due to what are its steps:

- Lean begins with determining the customer’s added worth.

- Processes and cycles for value stream or mapping.

- Recognize wastes and improve flow. To expose waste, data is collected and shared. This is the first step to improving the process.

- Next, discuss how to set it all up so it can start when the customer asks and deliver when necessary.

- Employees will be able to identify areas where they can improve and work together to fix them. This allows for process-wide thinking, and everyone is focused on meeting the customer’s needs.

But where is 6 Sigma in all this?

The method was developed by Motorola, and General Electric used it successfully at the time. Six Sigma, a process improvement technique that dates back to the 1980s, was first used by Motorola years later to reduce variability in manufacturing processes.

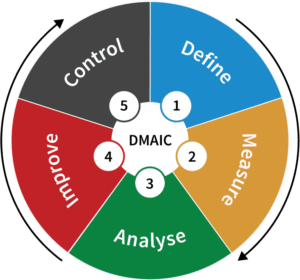

It follows the DMAIC structure, which ensures processes and wastes can be identified, measured, and analyzed. Then, they are improved and monitored to ensure that there is no change but continuous improvement.

The model can also be ordered in DMADV (Design for Six Sigma) or DFSS versions. Identifying and measuring the most important indicators within a company is possible. This will help you identify areas that need improvement.

Six Sigma provides managers with tools and targets to help them create a structured improvement plan.

Where Is LSS Left in This?

Lean Six Sigma was born in the USA. Its history is based on the fact that both Six Sigma and Lean Six Sigma combined achieved great manufacturing results in the late 1980s after Six Sigma was introduced.

It has since been used in many industries and is now a valuable addition to any curriculum. If you are interested in adding training and certification to your curriculum for value and learning a great methodology, don’t hesitate to contact Lean Six Sigma Curriculum Pros of Indianapolis!